Poly Pharmaceuticals Successfully Develops Ursodeoxycholic Acid (UDCA) Raw Material

Poly Pharmaceuticals has successfully developed Ursodeoxycholic Acid (UDCA) through synthetic biology technology.

The purity of the product is more than 99% through the genetically engineered strain using the method of multi-enzyme combined catalysis of specific substrates.

UDCA will be registered in markets including China, the United States, Europe, Japan, and South Korea in the future.

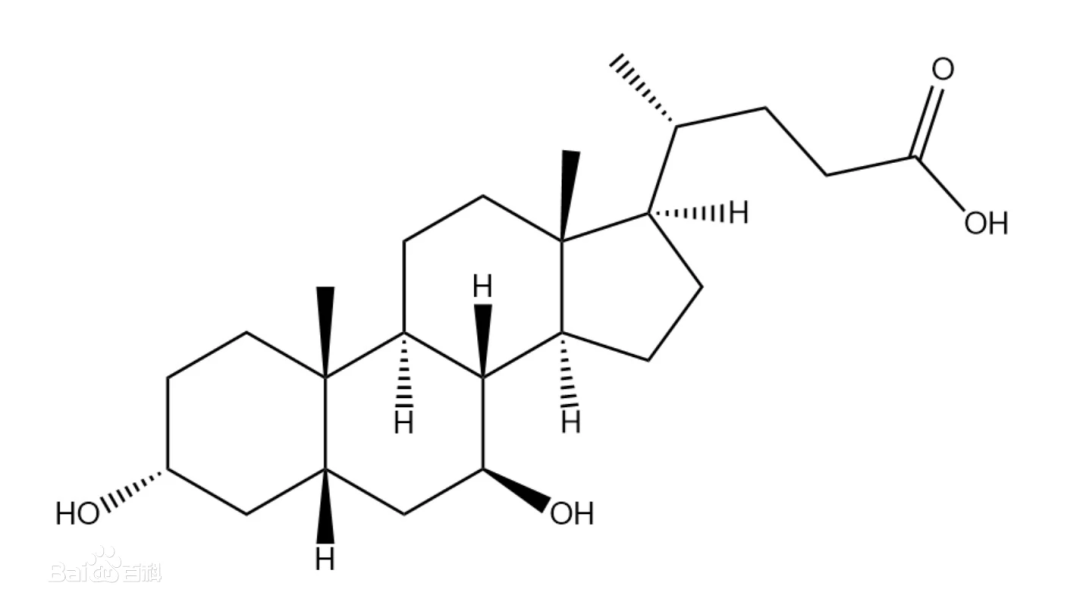

Ursodeoxycholic Acid (UDCA)

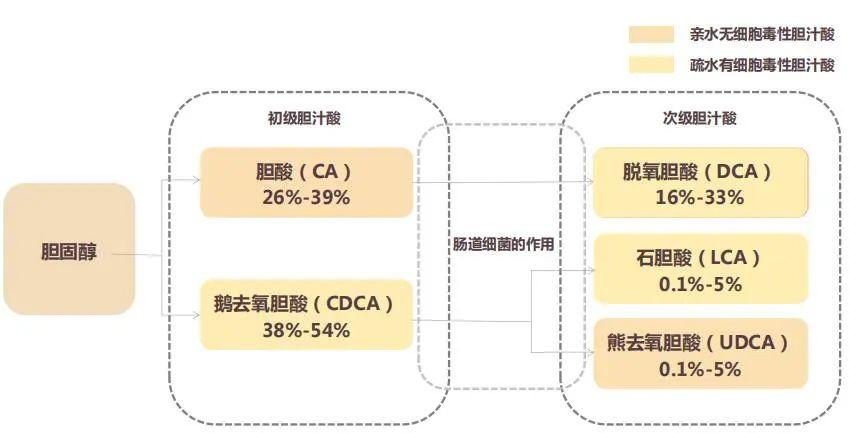

UDCA is a hydrophilic dihydroxy bile acid extracted from bear bile and is a unique component found in bear bile. In the human body, a small amount of UDCA is synthesized from chenodeoxycholic acid (CDCA) in the intestines through metabolic reactions, making up approximately 3% of the bile acids. UDCA can increase bile secretion, inhibit the cytotoxicity of hydrophobic bile acids, protect bile duct cells and liver cells from toxic bile damage, and improve the incidence and mortality rates of patients. Additionally, it can improve liver enzyme levels in primary biliary cholangitis (PBC) patients after liver transplantation, delay histopathological progression, reduce disease recurrence rates, and extend survival. In 1997, the US FDA approved UDCA as the only first-line treatment for PBC.

Initially, UDCA was extracted from bears, but due to its high medical value, there has been significant interest in developing synthetic UDCA through chemical and biological methods to meet clinical demands. Chemical synthesis typically uses readily available animal cholic acid (CA) as a starting material and undergoes oxidation-reduction to synthesize UDCA. While this method is straightforward, cost-effective, and mature, it faces challenges related to toxic chemical reagents and chiral issues, posing limitations for industrial technology transfer. In contrast, biological synthesis utilizes enzymes to catalyze the synthesis of UDCA, offering advantages such as environmental friendliness, simplicity, and efficiency, making it the mainstream method for industrial UDCA production.

Applications of Ursodeoxycholic Acid (UDCA)

UDCA can improve the saturation of cholesterol in bile, delay disease progression, and is the globally recognized first-line treatment for primary biliary cholangitis (PBC).

In addition to PBC, UDCA is widely used clinically for bile reflux gastritis, other bile duct inflammations, intrahepatic cholestasis of pregnancy, and liver protection in various disease contexts. The treatment of liver and bile diseases typically involves correcting causative factors, improving key indicators, reversing disease progression, and fully utilizing the liver's compensatory characteristics to enhance the quality of life for patients during the course of the disease.

In December 2022, researchers at the University of Cambridge published a study titled "FXR inhibition may protect from SARS-CoV-2 infection by reducing ACE2" in the top-tier academic journal Nature. The study demonstrated that UDCA could prevent SARS-CoV-2 infection and may have the potential to prevent infection by future mutant strains of the virus.

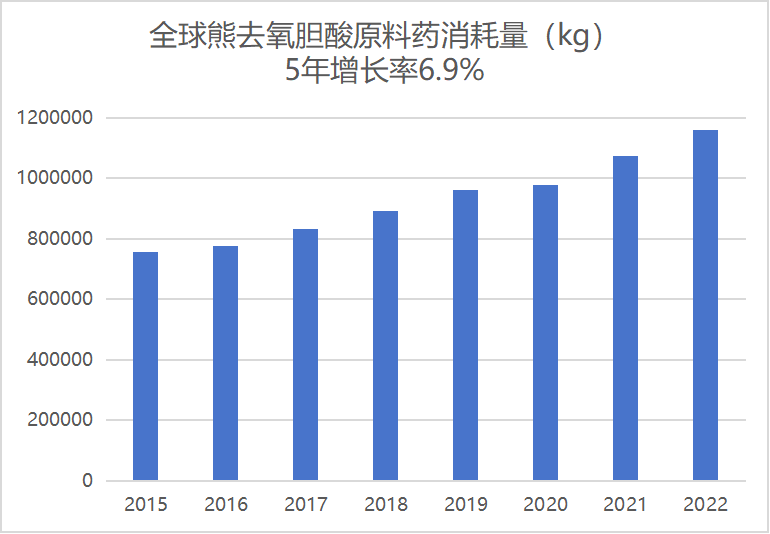

UDCA Market Capacity

IMS data shows that global UDCA sales reached 639 million tablets/capsules and consumed 1,158 tons of raw materials in 2023, with a long-term growth trend and a 5-year compound annual growth rate of 6.9%.

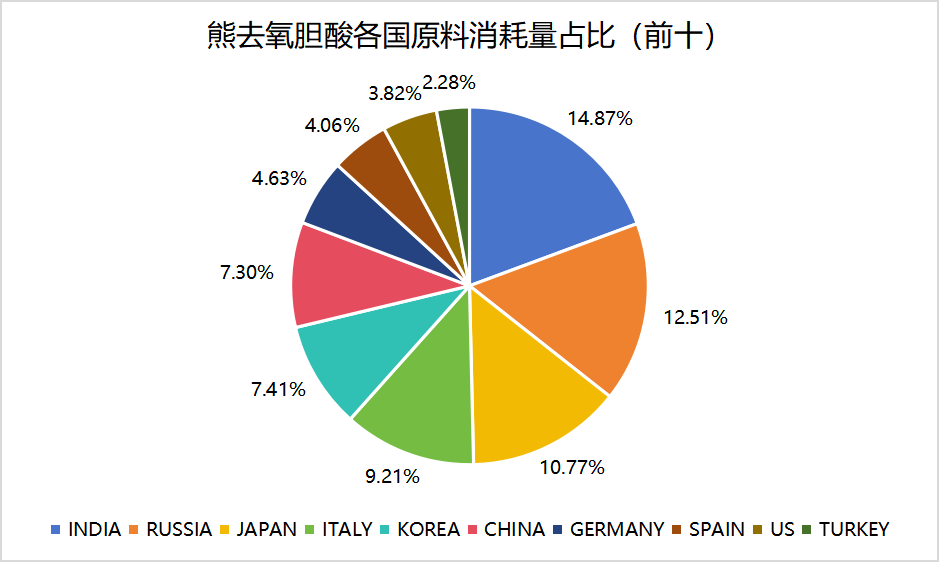

In 2022, Japan's UDCA raw material consumption was approximately 125 tons, accounting for 10.8% of global consumption. South Korea consumed approximately 86 tons, representing 7.4% of global consumption. Among European countries, Russia, Italy, Germany, and Spain all ranked in the top ten globally, with a total consumption of approximately 346 tons. The United States also ranked in the top ten in terms of consumption.

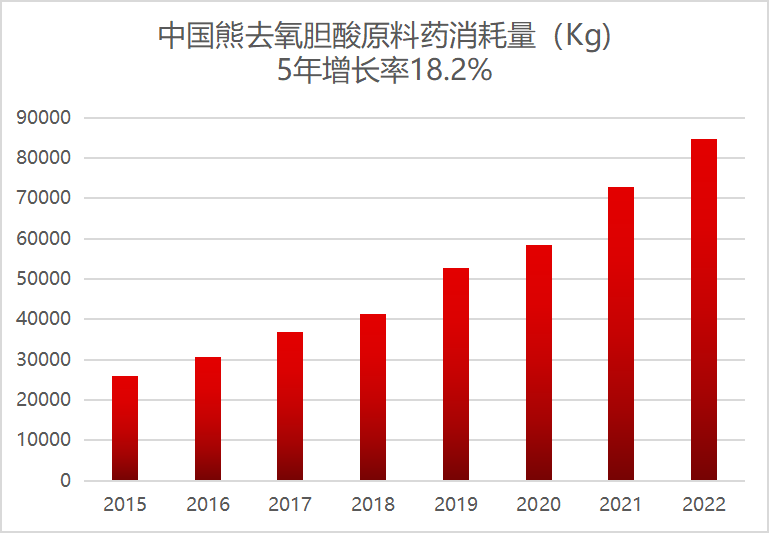

In 2022, China's UDCA raw material consumption was approximately 84 tons, accounting for 7.3% of global consumption.

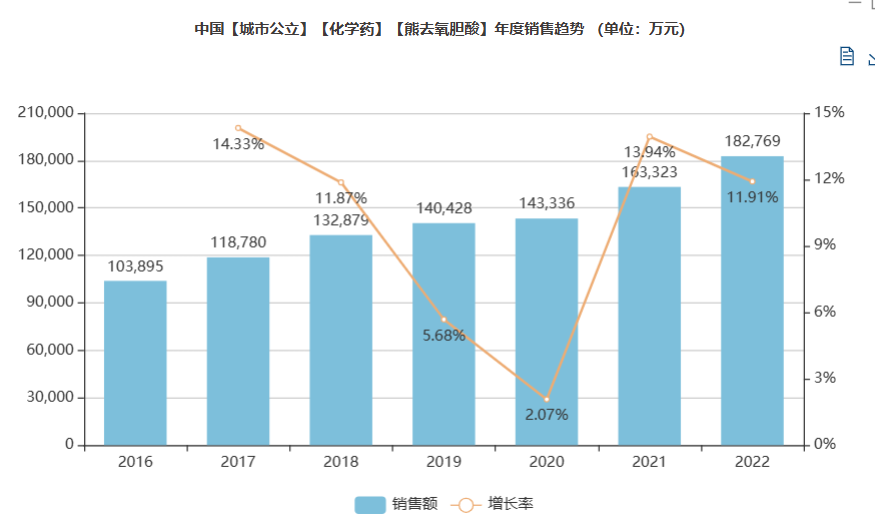

But compared with China's proportion of the world's population at 18%, there is still a large room for growth. UDCA is in a rapid growth phase, with a 5-year compound annual growth rate of 18.2%.

In fact, UDCA tablets/capsules have grown into a substantial market of 2.8 billion in China. Menet data shows that in 2022, the sales of ursodeoxycholic acid tablets/capsules in public hospitals have reached 2.56 billion RMB, and retail pharmacies have also reached 230 million RMB.

In 2022, UDCA tablets/capsules were included in the eighth batch of national volume-based procurement, with an initial purchase commitment of 127.47 million tablets/capsules. With increasing efforts in anti-corruption within the national healthcare system, volume-based procurement varieties and their APIs enjoy significant policy advantages.

As one of the research and development products of Poly Pharmaceuticals' synthetic biology platform, UDCA benefits from independently developed genetically engineered strains and reduced production costs through multi-enzyme catalysis technology. The commercial scale process development and product quality research have been completed, enabling the production of high-purity samples at kilogram scale.

Poly Pharmaceuticals' biotechnology research and development platform focuses on synthetic biology technology to manufacture high-value active compounds and essential pharmaceutical intermediates, contributing to original research and innovation in the biopharmaceutical industry.

In the future, Poly Pharmaceuticals' ursodeoxycholic acid will be registered in China, the United States, Europe, Japan, South Korea, and other markets to steadily and continuously serve global customers. Welcome to explore the global market of ursodeoxycholic acid capsules & tablets.

Home

Home